Earlier this year I was contacted by producer Richard about creating video and stills content for high end medical scrubs company Jaanuu. They had seen the industrial work that I had shot for Everlane, Nike and Zilingo and they were keen for me to visit one of their textile factories and to capture footage and stills of the manufacturing process.

A few days before the shoot I had a call with Richard and members of the Jaanuu creative team including Cameron, Sara and Olivia. Their brief was to capture the following:

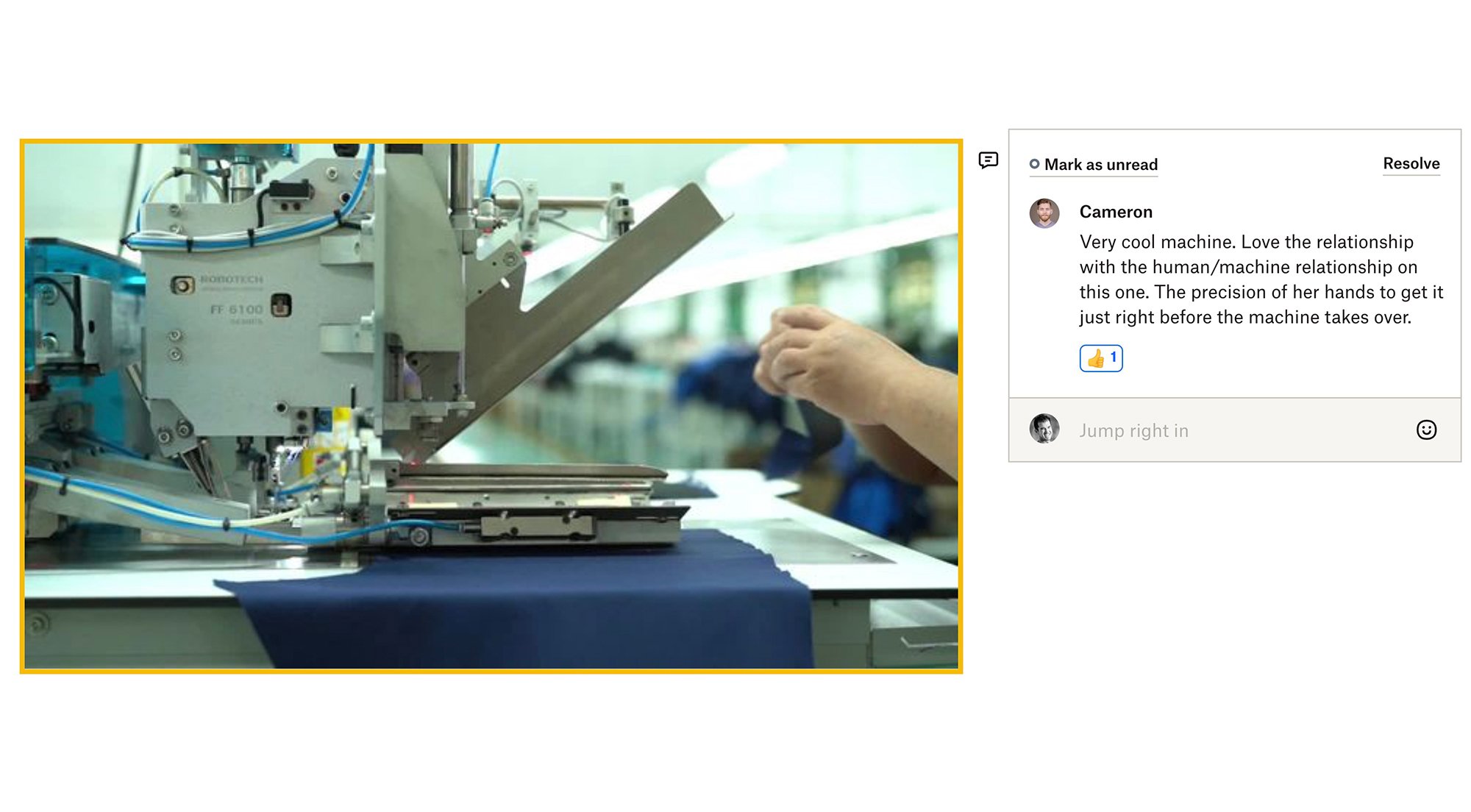

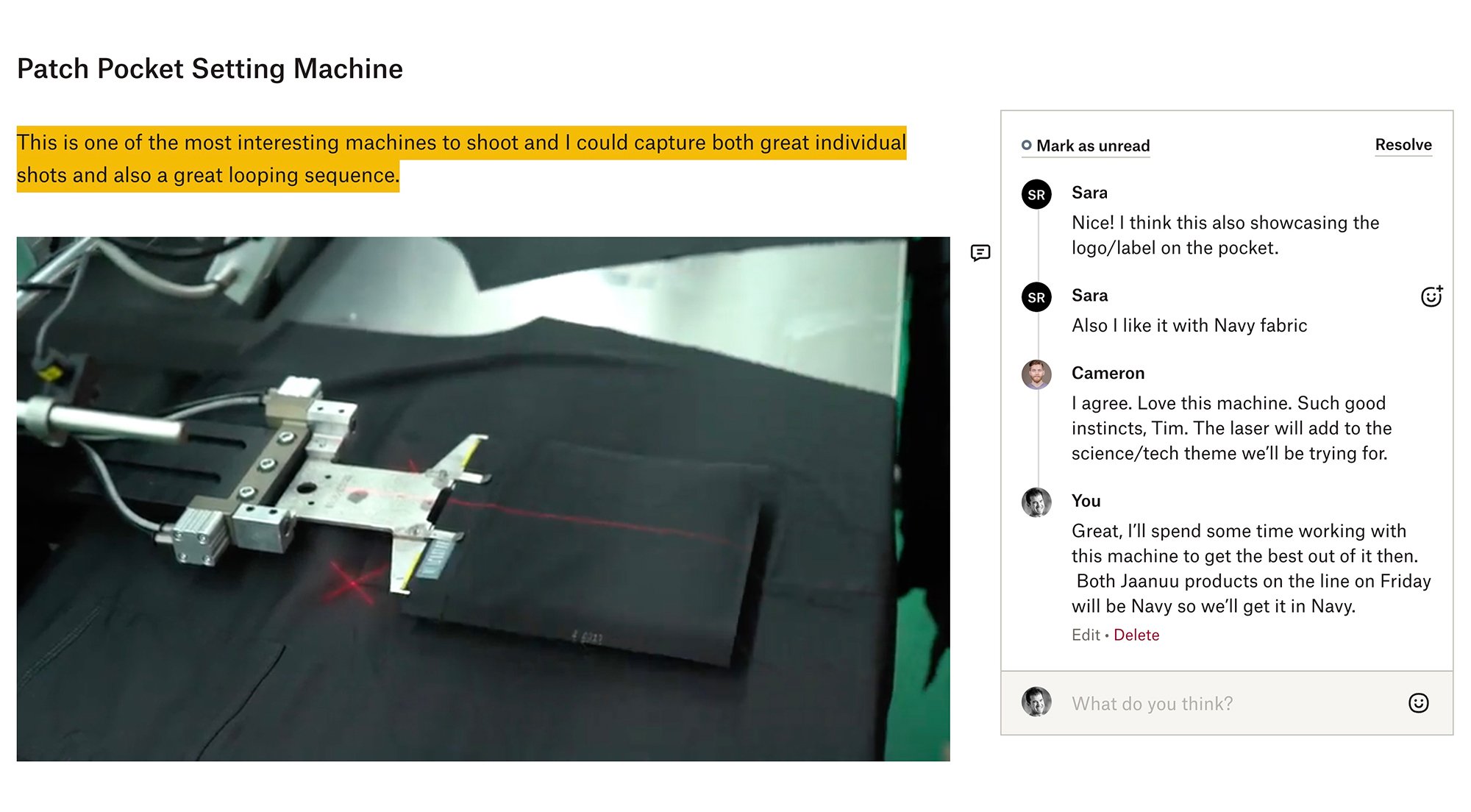

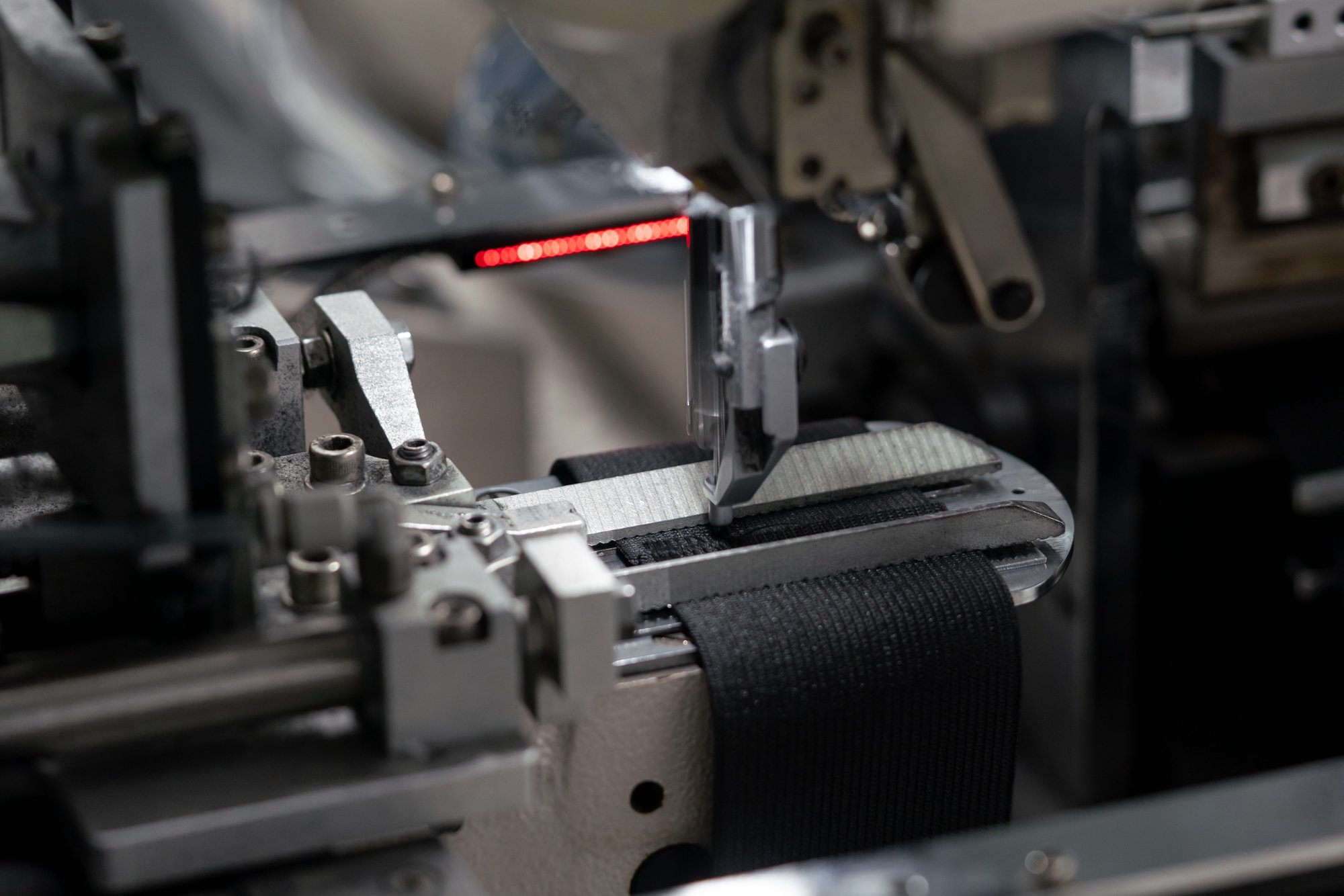

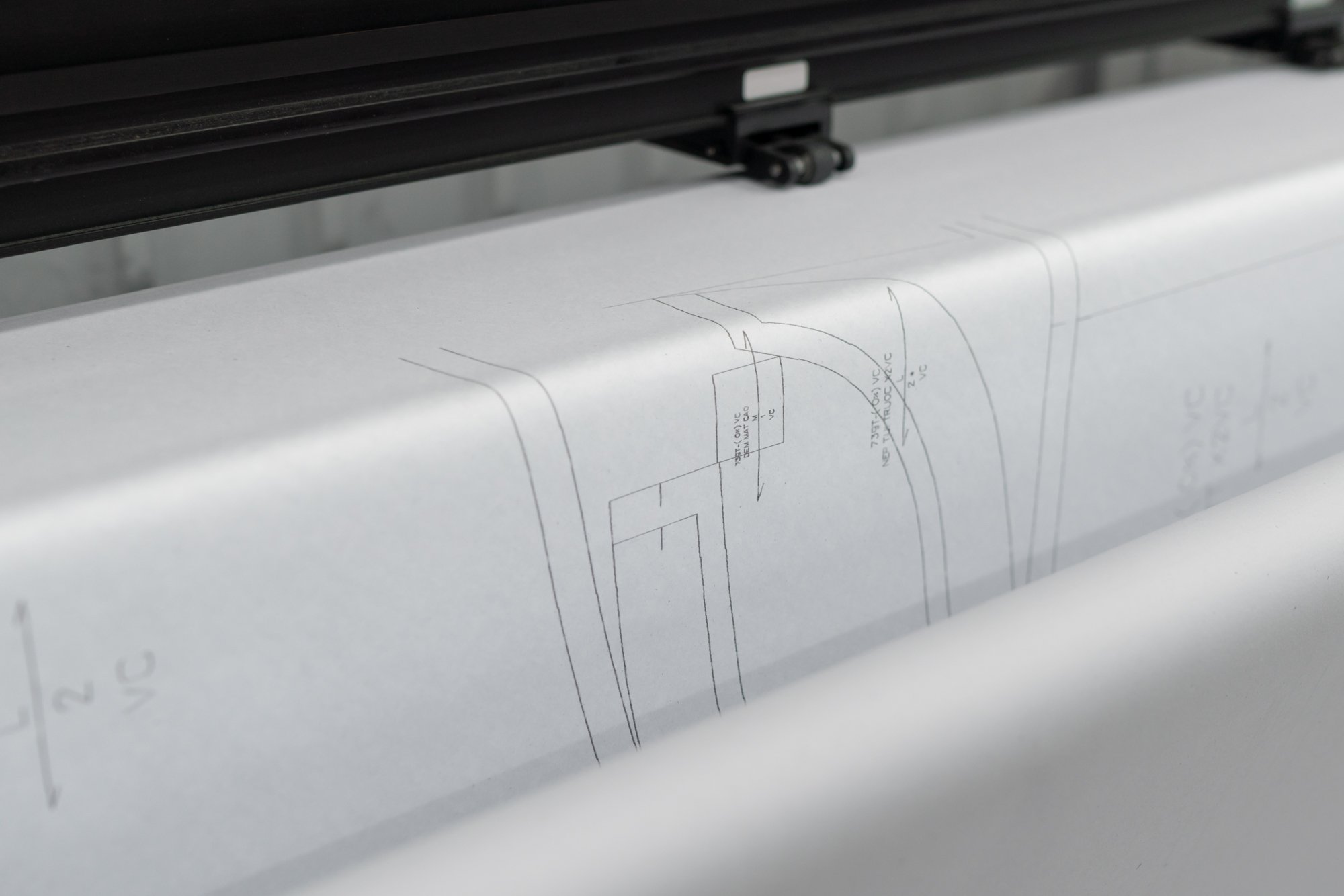

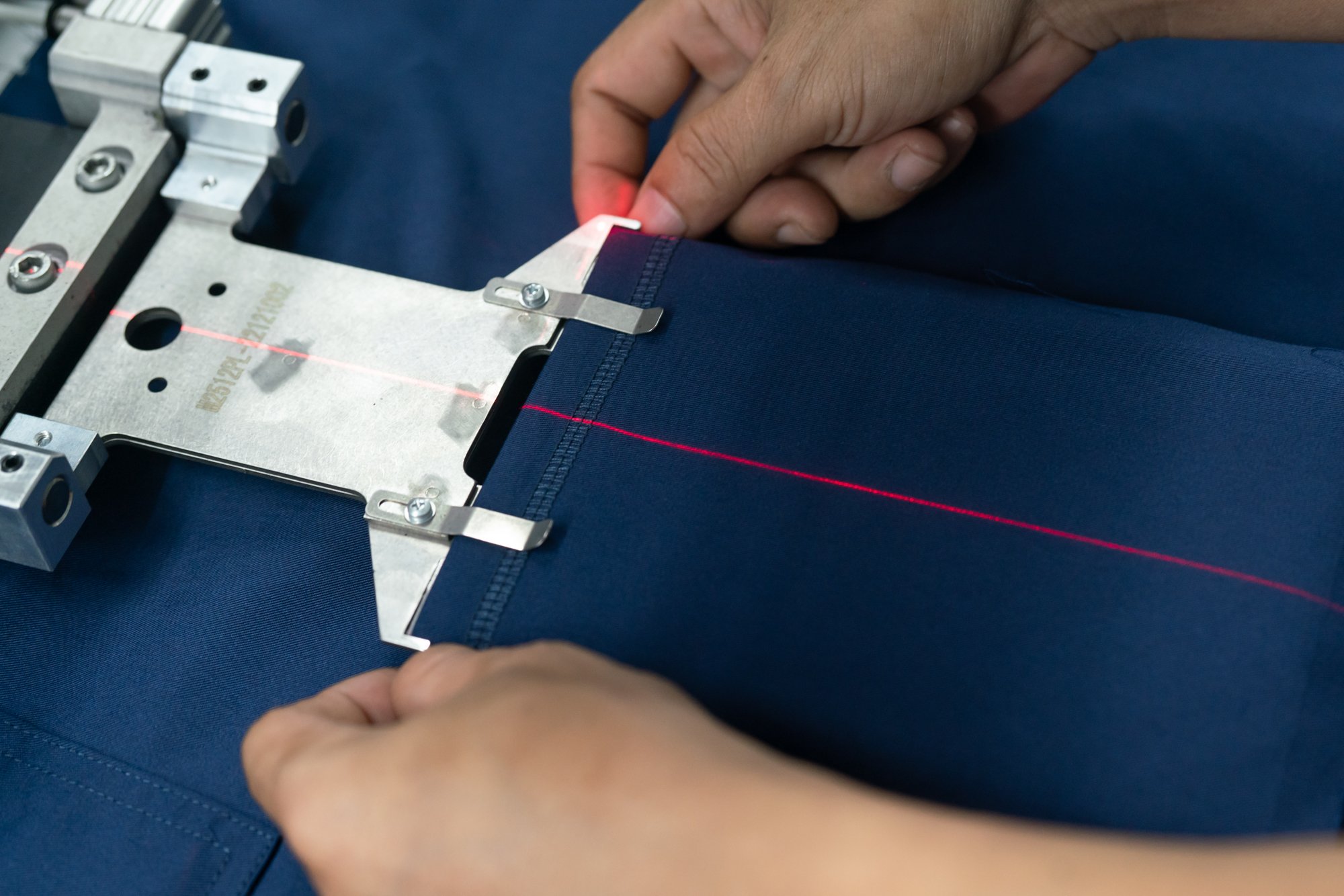

shots of machinery used in the manufacturing process

detail shots to showcase Jaanuu branding

capturing shots with lots of product in the one frame

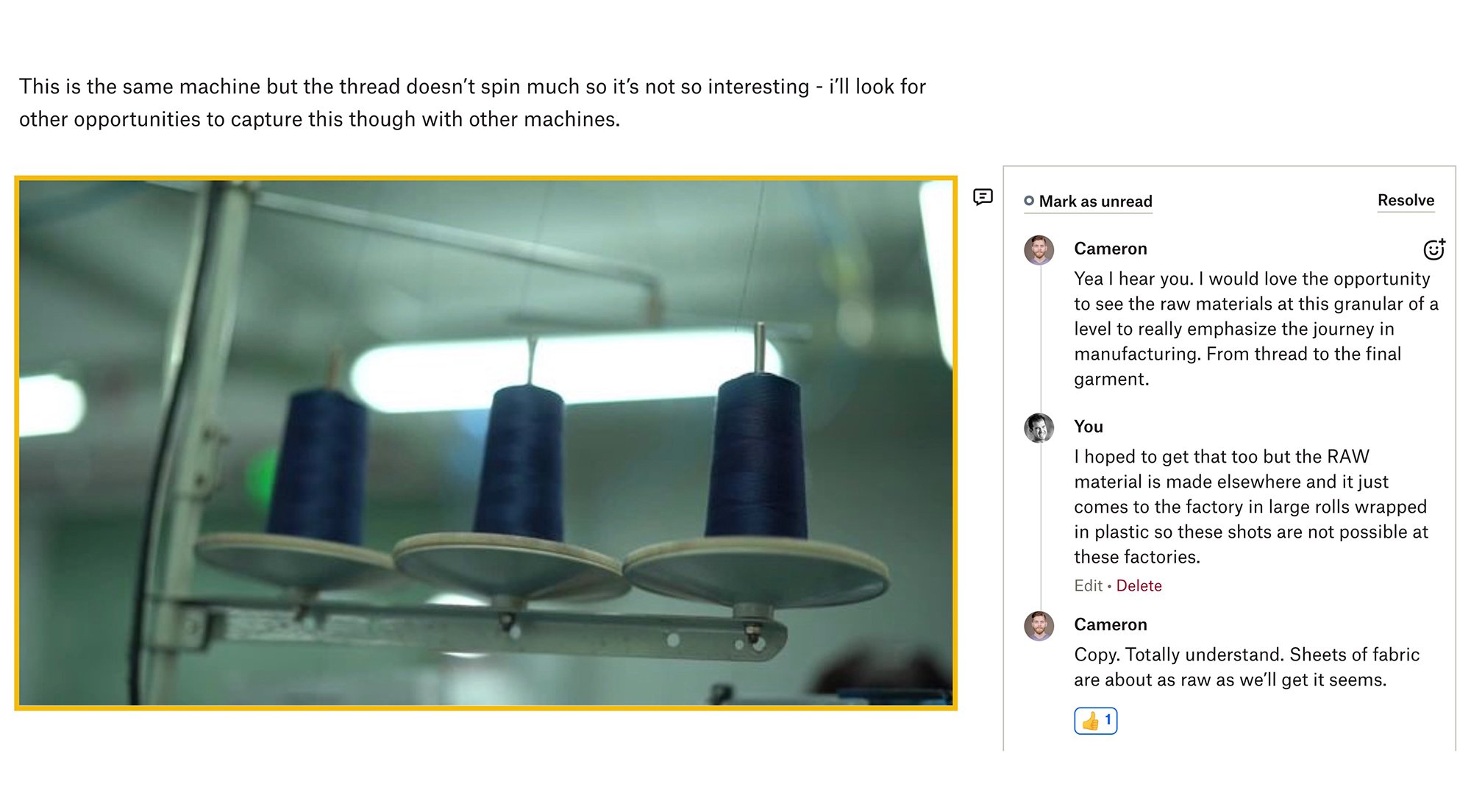

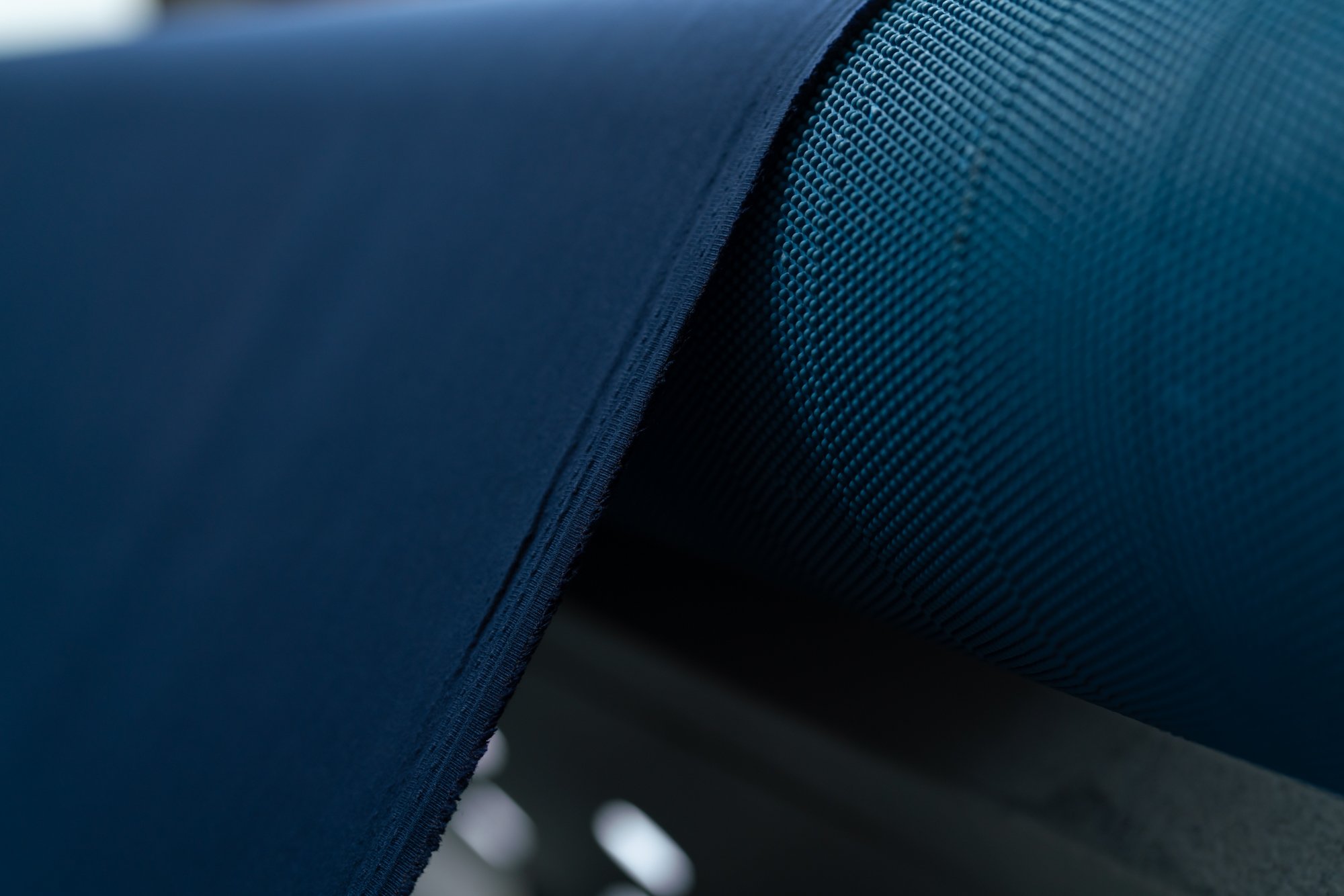

fabric focussed shots

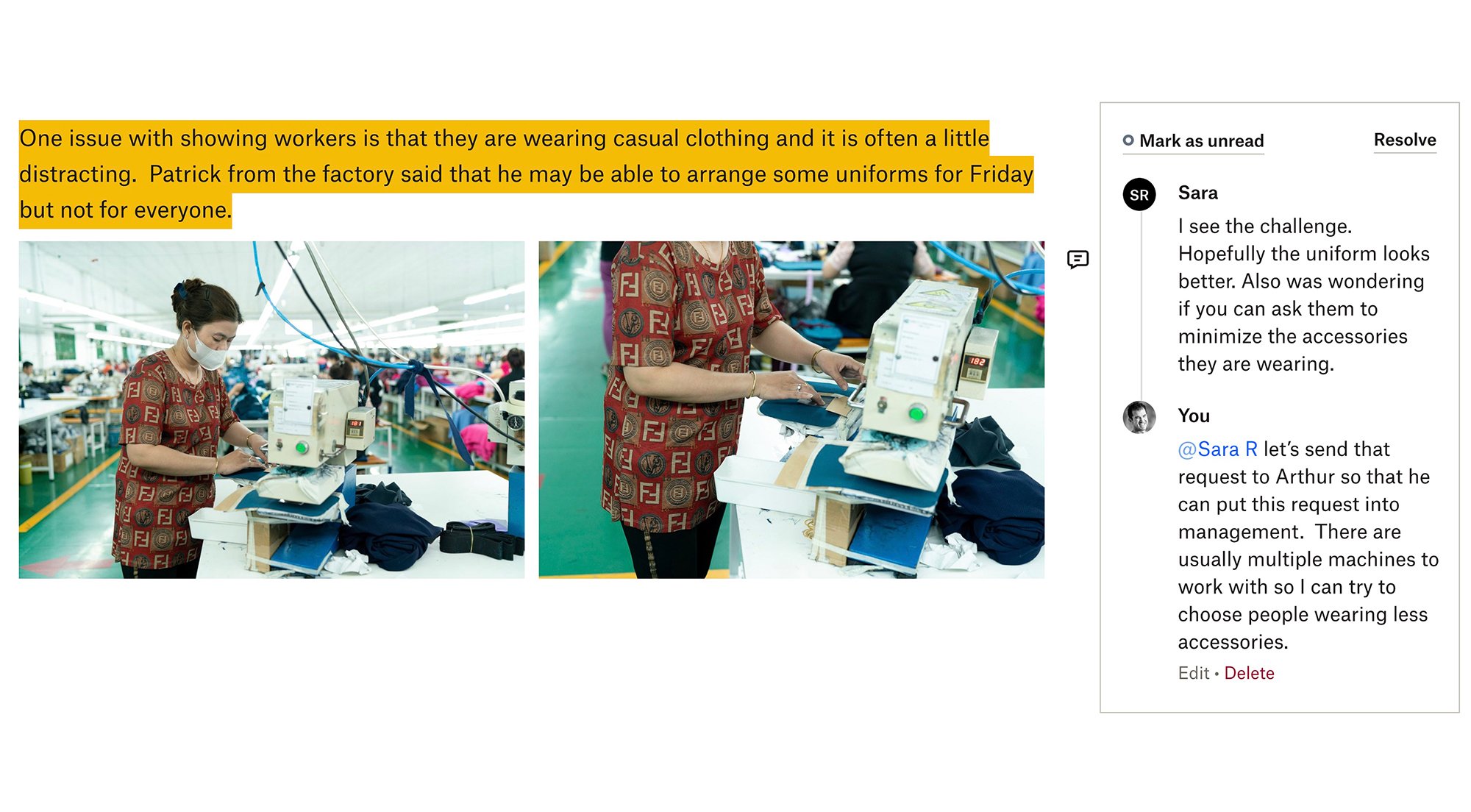

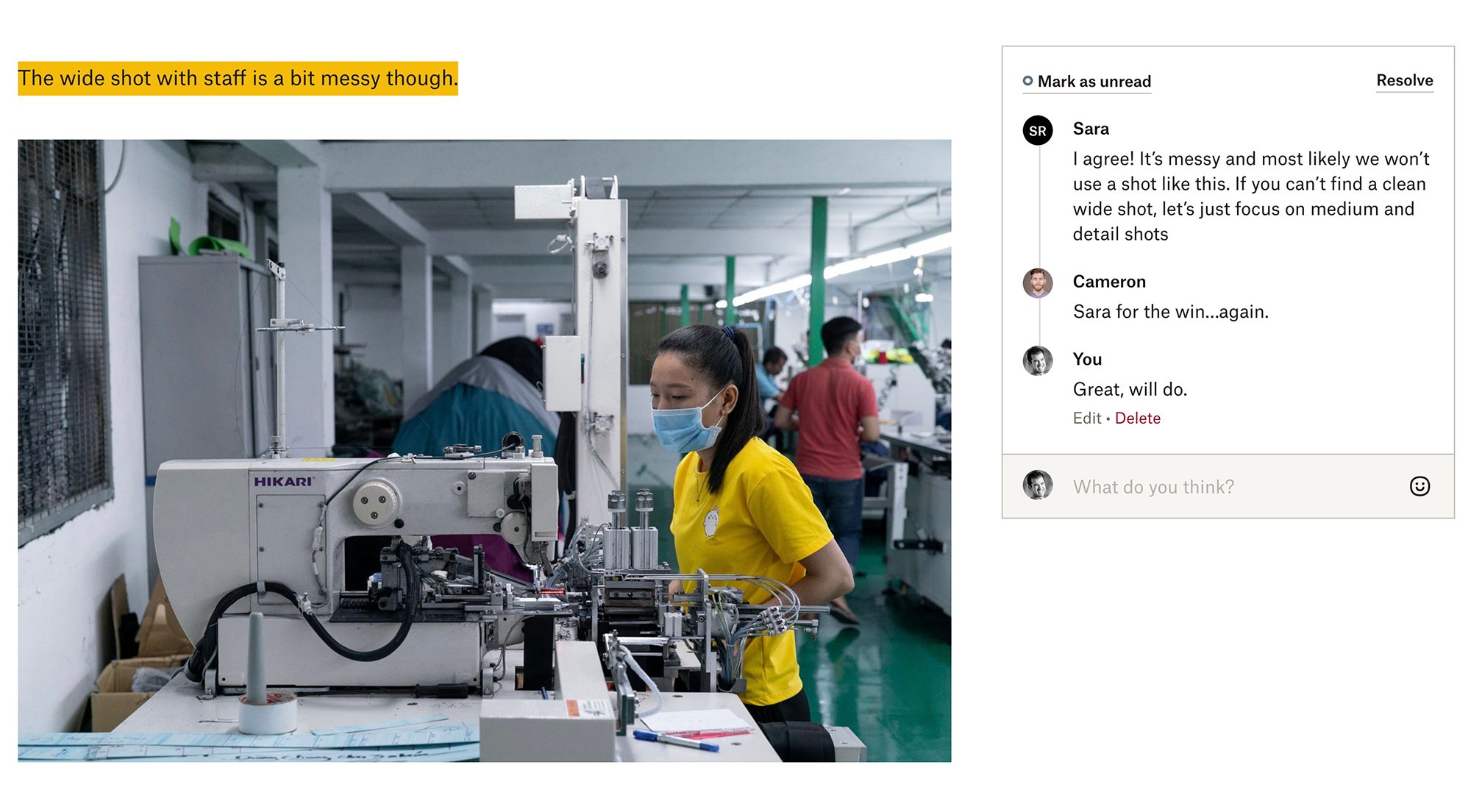

worker focused action shots

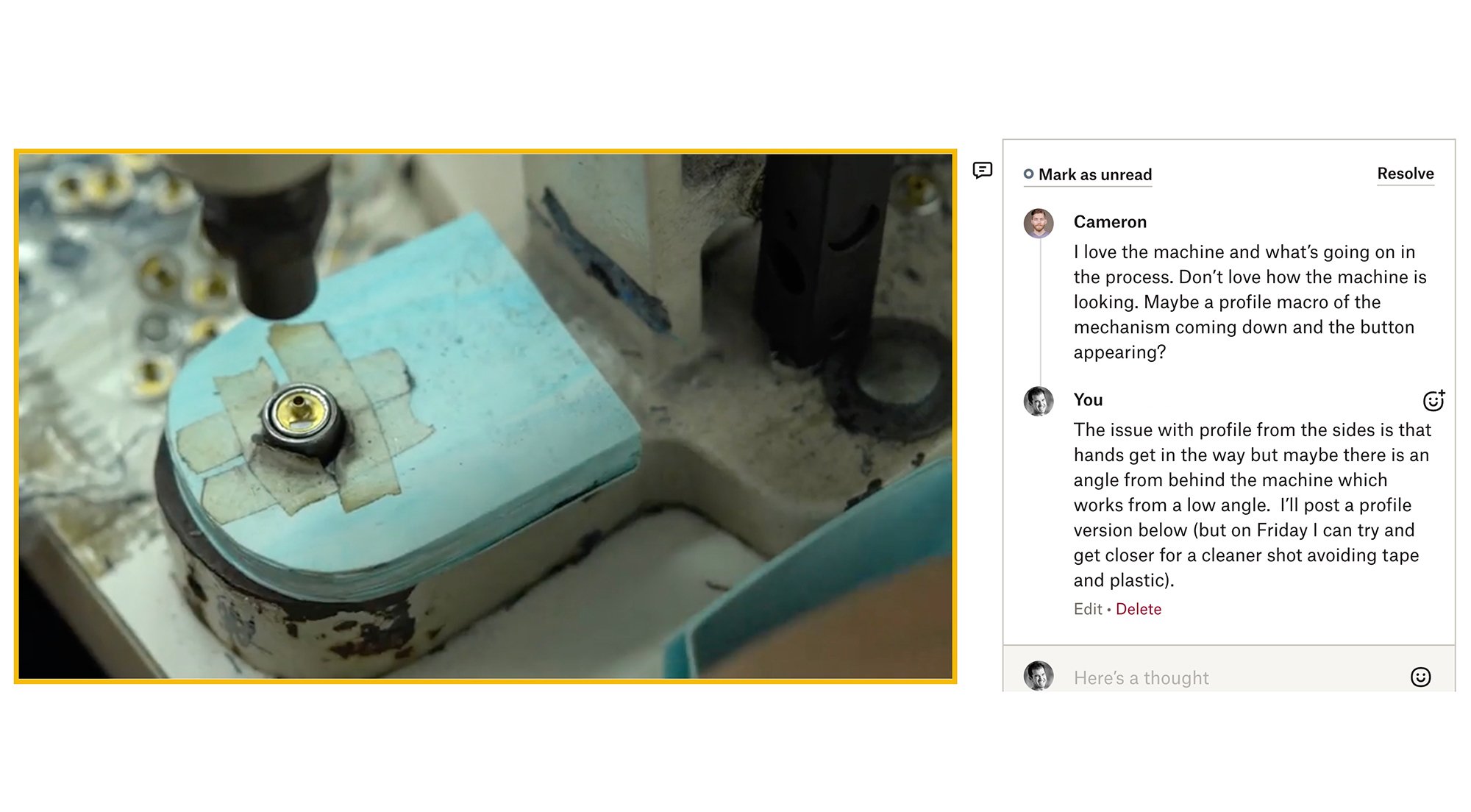

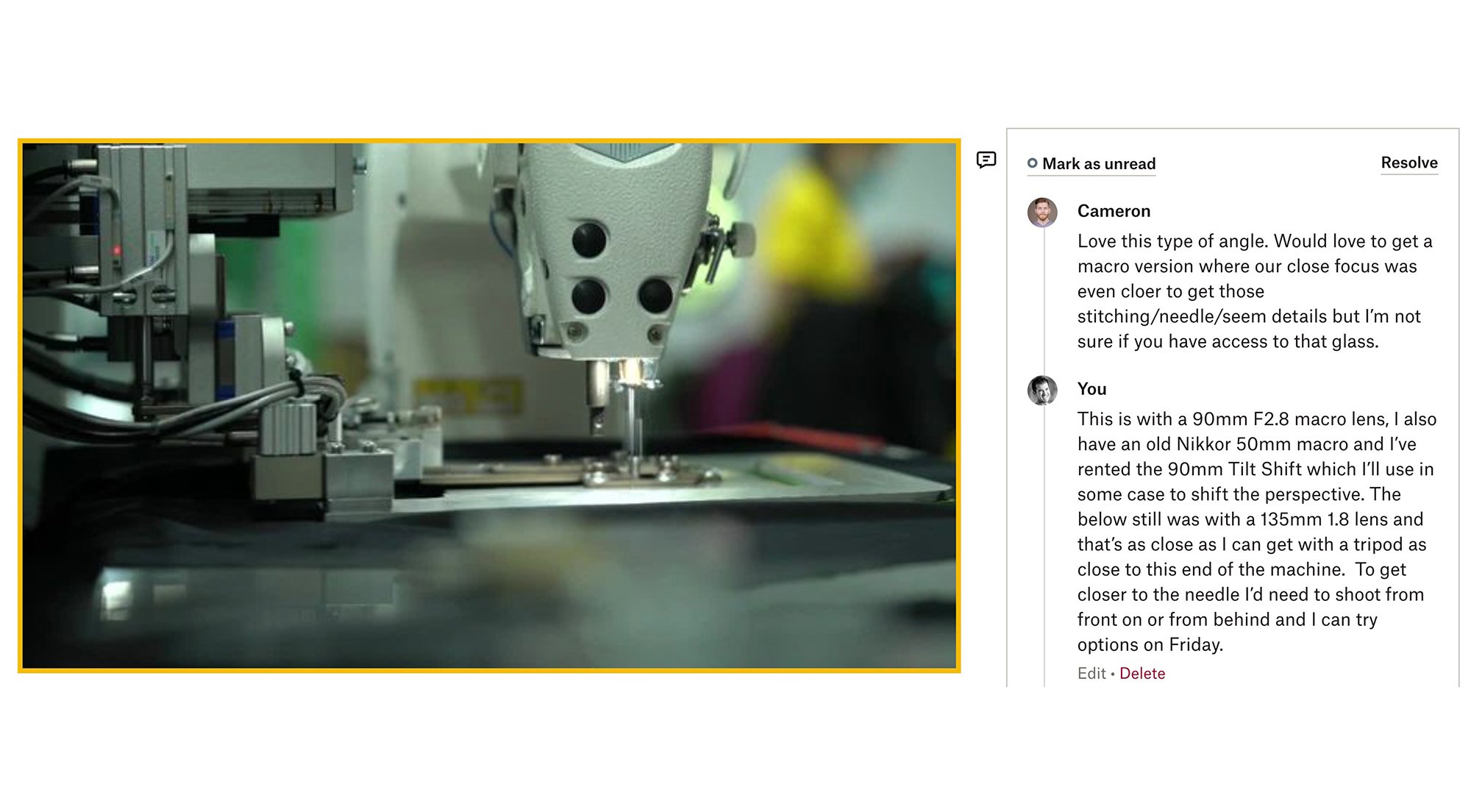

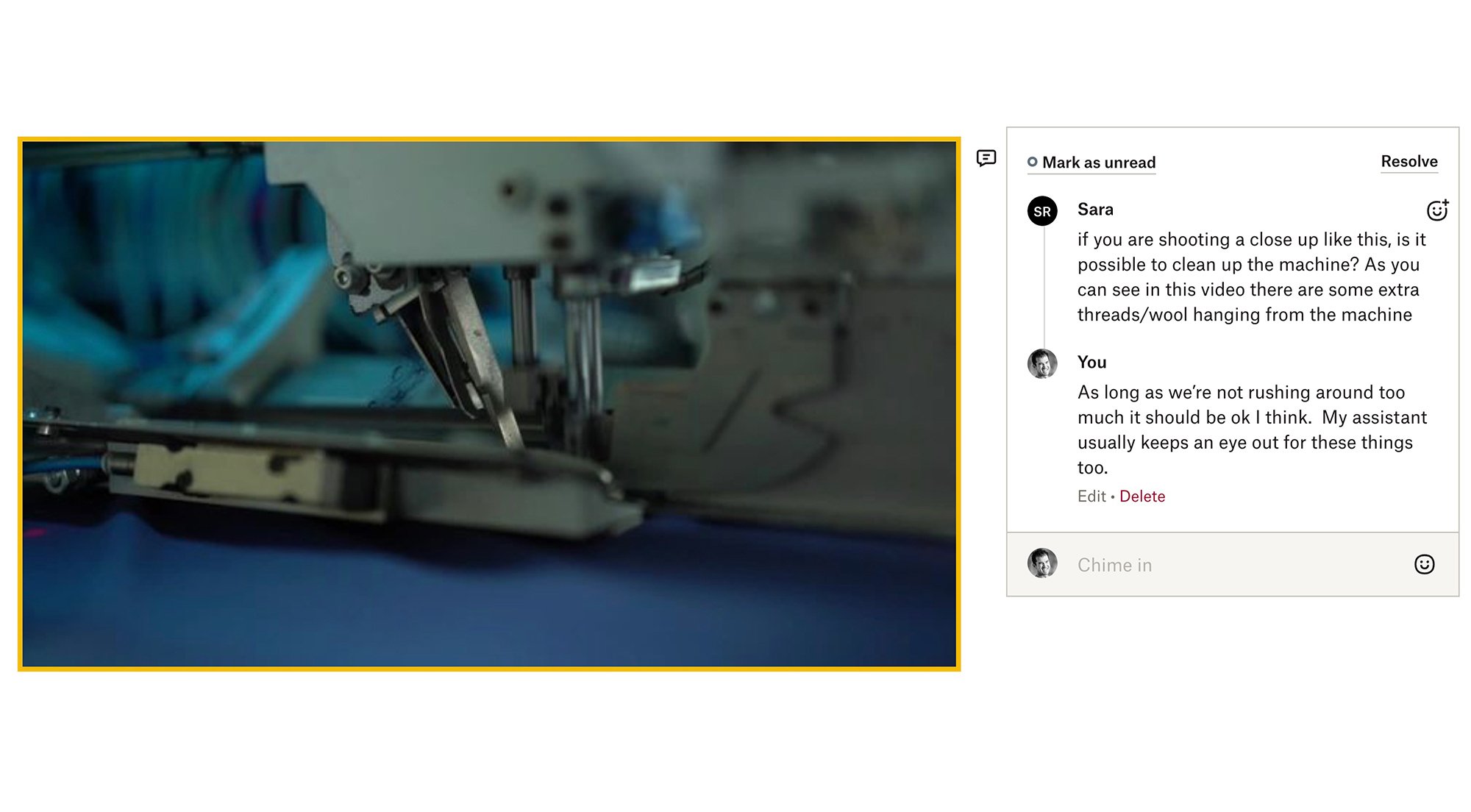

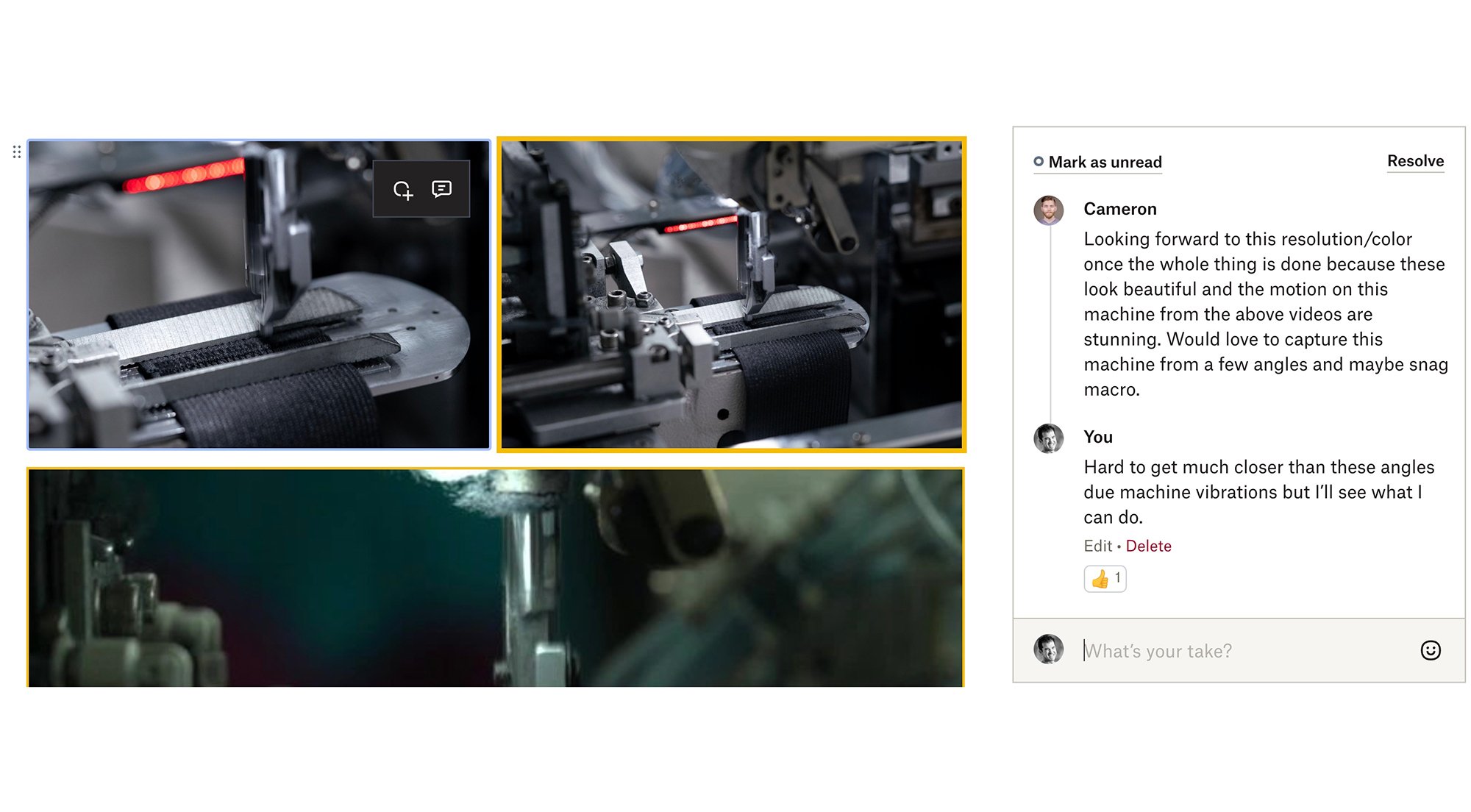

Cameron was editing a branding video for the company and the main focus of the shoot would be to capture video footage that would be used to launch their latest collections. He wanted well composed and very clean imagery and he was keen for me to look for abstract angles and to focus on capturing close up details. He wanted the footage shot in 60 frames per second slow motion in 4K resolution. To achieve this I rented the Sony FX3 and I shot the footage in a log picture profile which allowed for maximum flexibility in post production. Cameron planned to use very quick cuts of the footage so he preferred that I shoot everything locked off on a tripod.

In addition to the footage for the branding video Sara was keen for me to capture images and looping videos that could be used in social media and on their website. Sara also preferred that I capture images featuring navy fabric when possible and she wanted me to deliver images in both colour and in black and white.

During the call we decided that it would be best that I fly down to Ho Chi Minh City on the following Monday and then scout on Tuesday. I would then be able to upload imagery captured during scouting so that Cameron and Sara could give me feedback prior to the shoot on Friday.

Arthur from Jaanuu’s production team was visiting the factory during the shoot and I met him at the factory on the scouting day and he gave me a quick tour of the factory and showed me the machines that he thought would be ideal to capture. I then captured a wide variety of footage so that we could work out what machines to focus on.

At the end of the day I uploaded the best of the work on to dropbox paper and Cameron and Sara then went through it and gave me a lot of fantastic feedback. Below are some screenshots of our discussions.

Having realised that the factory was a little messy and that some of the staff would be wearing casual clothing they decided it was best to avoid wide shots. They also asked me to try and clean the machines of dust and loose threads and they wanted me to ask the staff to remove accessories such as rings and bracelets.

Arthur had informed me that the first products on the line would be navy but unfortunately when I arrived on the shooting day there was only one Jaanuu product on the line and it was a design featuring black fabric. Arthur made a quick call to Olivia to let the creative team know the issue and we decided to try to capture as many of the processes as possible using navy fabric and Olivia said it was ok to shoot the Jaanuu product on the line with black fabric.

To get around the issue my contact at the factory had the staff prepare small amounts of navy fabric so that they could run it through the machines and allow me to get a range of shots of each machine. In a normal situation on a factory shoot there is usually an abundance of fabric going through a machine and I am able to watch the process first and shoot in a documentary style as I observe first and then frame the shot and record for as long as is needed with the freedom to get several takes or to make slight adjustments until I get it right. With only a small amount of navy fabric to work with though I had to get the factory workers to put 1 piece of fabric through at a time and often I only was able to get 1 take of each angle.

For each machine that we shot I captured the video footage first and then I captured some stills of the more interesting moments and angles.

Despite the difficulties we managed to get some really fantastic shots and I’m particularly happy with the selection of shots that they used in the branding video.

Jaanuu’s 30 second branding video which features some of work at the midway point of the video. There is longer 1 minute version on the Jaanuu About Us page which features more of my work.

They have also been using some of my stills and video in their instagram reels and I really like the way they have cut my work with their other branding materials.

The shoot went really well and I received fantastic feedback from Richard and the creative team. I’ll finish off by sharing a gallery of my favourite stills, the six looping videos that I edited and colour graded for them and another screenshot from the Jaanuu website featuring my work.

A behind the scenes look into the creation of video and stills content of the manufacturing process for high end medical scrubs company Jaanuu at one of their textile factories in Ho Chi Minh City.